Our quality management system makes it possible to trace completely all production phases in order to guarantee strict adherence to customer's requirements. From raw material acceptance up to final inspection, trained and experienced operators supervise the whole production process to assure high-quality standards and full compliance with tolerances.

Our R&D department mainly ensures the quality of the product which is a very important factor when producing forgings, casting, machining, fabrication and etc no matter if it is relating to the Auto Parts, Two Wheeler Parts, Railway Parts, Hardware Components, Tractor Parts, Hand Tools, Forging Components or Allied Industries. Quality is a vitally important part of our companies.

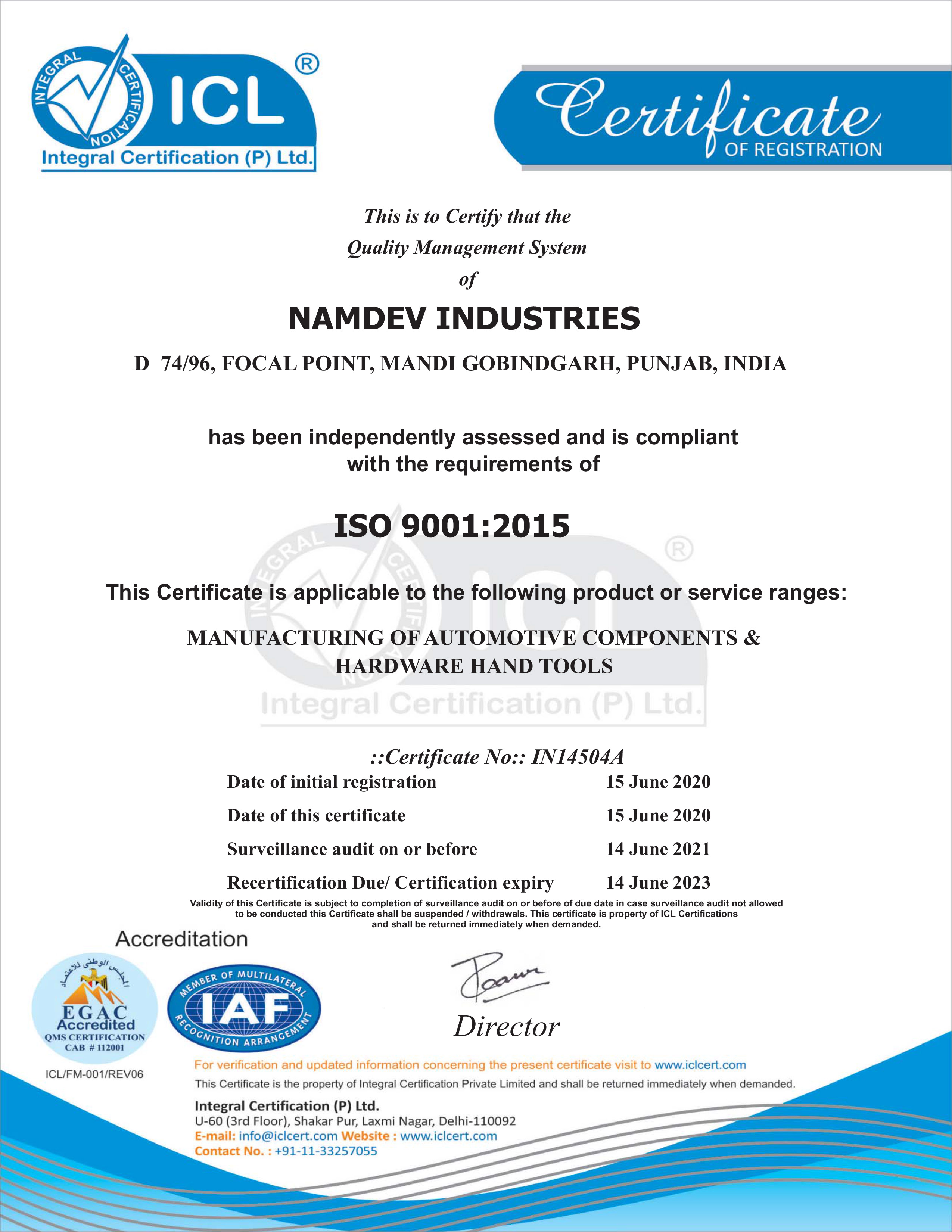

- An ISO 9001:2015 & TS 16949:2009 Certified Company.

Quality

Quality Assurance

Identified the process needed for the quality management system & their application throughout the organization it includes.

- To review customer requirements.

- To review the customer complaints

- To purchase the material as per requirements.

- Calibration activities.

- Inspection & testing activities.

- Corrective & preventive activities.

- Storage, handling & preservation activities.